Transparency and accuracy are a key advantage to working with EdgeBuilder on your projects; from initial estimates to finished panels, we establish excellent communication throughout the process. We often get questions from our clients regarding our plant and how our panels are created. Let’s take a short tour of the facility and our process.

To start, once we’ve received plans and specifications from our clients, a detailed panelized design of the building is completed by our in-house design team using specialized software. It’s here where the magic begins!

The design team then sends the panel designs to the plant, where the virtual panels are imported into the plant computers. This includes the computer running the saw, where thousands of pieces are cut every day.

We then put the wood into our specialized Hundegger Speed-Cut Sc1 saw where the pieces are cut and labeled according to how they are to be assembled.

Inserting the wood into the Hundegger Speed-Cut Sc1 saw.

Examining the wood after being cut.

Pieces are quality checked multiple times throughout the entire process—from being cut, labeled, and loaded—to ensure they are the correct specifications. Here’s one of the first quality assurance (QA) checkpoints.

Wood being labeled.

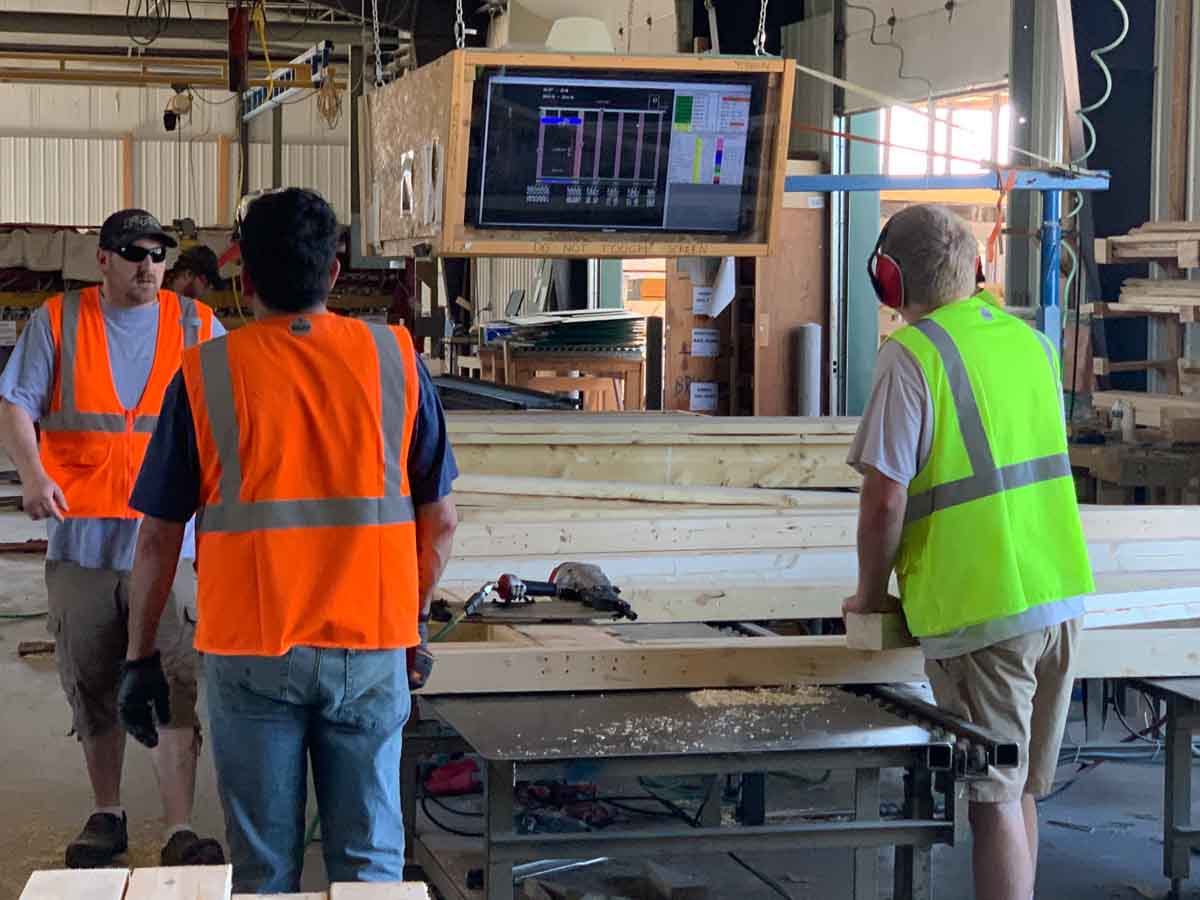

Once a piece is cut, it’s loaded onto the assembly line with the rest of the order. Our skilled craftspeople construct the panels, examining pieces as they’re handled, so that our clients receive completed panels that are square and easy to work with when they reach their destination.

Assembling panels to their specifications.

Mid-assembly quality control.

Checking that panels are square and the correct measurements.

Next, we add sheathing and perform final quality checks before getting them ready for transport.

A craftsman adds the sheathing.

Final quality check before loading.

For the last phase of production, we organize and bundle the panels in the order that they will be assembled. For our clients’ convenience, we can ship them in small bundles (upon request) to lessen the demand onsite for space to store the pre-made walls. Yard managers are always on-hand to ensure bundles are loaded safely whether they’re traveling a short or long distance.

Are you interested in high-quality work from craftsmen that produce some of the best wall panels and permanent wood foundations in the business? Call EdgeBuilder to start working with our experts on your next project.

Recent Comments